Micromachining

A History of Precision: The Invention and Evolution of Swiss-Style Machining

In the late 1800s, a new technology — Swiss-type machines — emerged to serve Switzerland’s growing watchmaking industry. Today, Swiss-machined parts are ubiquitous, and there’s a good reason for that: No other machining technology can produce tiny, complex components more efficiently or at higher quality.

Laser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

Read MoreMaking Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

Read MoreKeeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

Read MoreUnderstanding Micro-Milling Machine Technology

Micro-milling can be a companion process to turning-based production machining. This article looks at some of the technologies that go into a micro-milling machine and why they are important to successful operation.

Read MoreMicro-Drilling: 9 Questions to Answer Before Beginning

Applications for micromachining continue to grow. Successful machining with small tools calls for a different set of process skills on the shop floor.

Read MoreMicromachining Turns Images of the Queen into Tiny Portraits

Engineers at the University of Sheffield Advanced Manufacturing Research Center (AMRC) used a turn/mill center to reproduce a series of tiny portraits of Queen Elizabeth II, down to only 1.4 mm wide, onto brass.

Read MoreProducing Micro Screws for the Watch Industry

Cutting tools play a key role in machining tiny screws on Swiss-type lathes for this Switzerland-based watch manufacturer.

Derek Korn

Editor-in-Chief, Production Machining magazine

Walter Micro Drill Has Internal, External Coolant Capabilities

Walter USA’s Supreme DB133 solid carbide micro drill delivers high precision and productivity.

Read MoreSpeed Matters in Microtooling Applications

A variety of tooling spindle options brings micromachining work within reach for shops looking to expand their capabilities.

Read MoreMeasuring the Merit of Ceramic Cutters

In testing new ceramic microtools, a precision dynamometer ensures that cutting forces are measured precisely so tool performance parameters can be determined.

Read MoreBurr-Free Micro Thread Whirling

Threading is usually the last operation when machining components, which is why the process needs to be reliable and highly precise. DC Swiss has developed an internal thread whirler, which leaves micro threads burr-free, even in demanding, hard-to-machine materials.

Read MoreMicromachining is About Precision

Holding tolerances on very small part features is not for the faint of heart. The skill is not only in the machining, but cleaning and inspection as well.

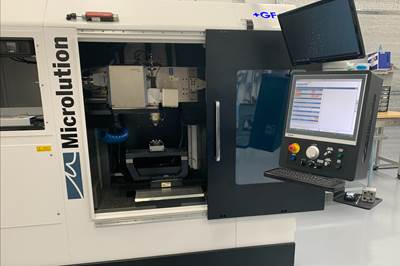

Read MoreLaser P 400 U Five-Axis Machine Incorporates Dual Laser

GF Machining Solutions’s high-performance Laser P 400 U five-axis machine can machine small, intricate parts with a dual laser head that incorporates both a fiber nanosecond laser and a femtosecond pulsed laser.

Read MoreAddressing Micro-Boring Challenges

This boring bar/tool holding system for Swiss-type lathes is said to offer high rigidity and positioning repeatability. In addition, the boring bars can be changed out using no hand tools.

Derek Korn

Editor-in-Chief, Production Machining magazine

Choosing the Right Toolsetting and Detection Technologies

Investing the time to invest in the right machines can mean the difference between a profitable operation and an ongoing headache.

Read MoreManufacturing Efficiently at a Micron Level

Grinding very small-diameter instruments for use in medical procedures is a niche business for this micro-grinding machine manufacturer. The company makes machines that use a variety of grinding techniques to manufacture guidewires for the medical industry.

Read MoreMicromachining in a Big Way

With the acquisition of a new CNC Swiss-type lathe, this company can now bid on small, complex parts it wasn’t able to in the past, while also slashing setup and cycle times.

Read MoreA Youthful Approach to Production Machining

Growing up in the industry helped this young shop owner learn key strategies for getting the most from his machines.

Read MoreMilling Hard-to-Machine Materials on a Micro Scale

The idea of a tool that effectively controls heat with a special grade of carbide, a new coating and internal channels that deliver cooling through ports in the shank where the milling flutes begin, is worth a look.

Read MoreMicro Deburring Gets Hot

“Micro deburring,” a name commonly used to describe the deburring of tiny small parts, is often considered more of an art than a science. Although this is true to some extent, deburring micro parts does not always have to require hand manicuring parts with a scalpel under 10× to 20× magnification.

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Lori Beckman

Executive Editor, Products Finishing

Machining Center for Small Workpieces

Here’s a different approach to a micromachining center--a machining strategy developed around interpolation, allowing machining operations to benefit from the dynamic control of the worktable while reducing the number of tools needed.

Read MorePurpose Built Micromachining Center

In metalworking, it is rare to find new approaches to well-established technologies; usually new developments are major or minor upgrades to known elements. This micromachining center is rewriting the rulebook.

Read MoreSmall Machines for Micromachining

Proper tooling and machining options are critical in developing an optimized plan for micromachining.

Read MoreAccuracy Helps Swiss Watches Keep Perfect Time

Production engineering solutions required by many Swiss watchmakers are already installed in their CNC machines when they buy them.

Read MoreApplying Waterjet Micromachining

Scientists are deeply involved in exploring the frontier of micro-abrasive waterjet technology.

Read MoreMicro-Boring Tool Calms ‘Perfect Storm’ for Medical Parts Fabricator

In one of its first commercial applications, an Ingersoll micro-boring tool has brought process stability to a machining application that the user describes as a “perfect storm.”

Read More

.jpg;maxWidth=300;quality=90)